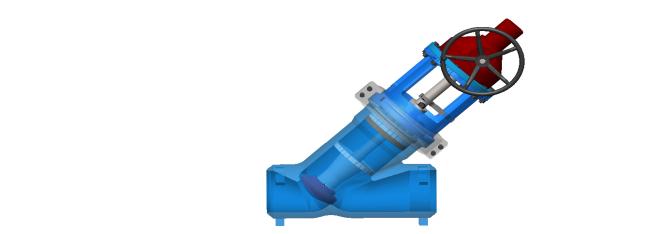

Khoom tsim nta

Hydrogenation thev naus laus zis rau roj av yog txheej txheem tseem ceeb hauv cov khoom siv roj av, hloov kho thiab ua cov roj hnyav.Nws tsis tsuas yog tuaj yeem txhim kho qhov tob ntawm cov txheej txheem thib ob rau cov roj crude thiab cov nqi rov qab ntawm lub teeb hydrocarbon, tab sis kuj ua kom cov roj zoo thiab txo cov pa phem ib puag ncig.Yog li ntawd, kev kho hydro, hydro cracking lossis Residue hydro kho thiab lwm yam hydrogenation system tau dhau los ua qhov tseem ceeb ntawm chav ua kom zoo.Hydrogenation Unit yog nyob rau hauv cov hluav taws kev pheej hmoo hluav taws kub chav kawm A, nws yog ib qho tseem ceeb technical nta yog kub, kub siab, hydrogen hloov dua siab tshiab.Hydrogenation siab siab li qub yog: cov cuab yeej siv siab, nruj zoo, kev nyab xeeb thiab kev ntseeg tau.

Valves rau lub siab hydrogenation muaj cov yam ntxwv hauv qab no, ntxiv rau kev ua haujlwm ntawm cov li qub:

1.Nws tshem tawm cov pa tawm ntawm qhov nruab nrab los xyuas kom meej sealing kev ua tau zoo ntawm lub valve, hom kev sib txuas ntawm lub cev thiab qia yog siv rau lub siab kaw, thiab lub kaus mom, lub nplhaib sib khi thiab plaub lub nplhaib, thiab lwm yam suav nrog tag nrho raws li EN 12516- 2 kom tsis txhob xau.

2.Lub cev muaj kev ntsuam xyuas kev ntxhov siab nyob rau hauv lub sijhawm ua haujlwm nrog ANSYS kev soj ntsuam software, thiab lub kaum sab xis ntawm qhov kev ntxhov siab yog ua los ntawm kev soj ntsuam kev ntxhov siab ntawm cov yeeb yaj kiab kom ntseeg tau tias lub cev deformation, txhawm rau kom tsis txhob muaj kev cuam tshuam sab hauv.

3.Cov ntim khoom yog cov ntshiab graphite (cov ntsiab lus ntshiab carbon ≥95%) thiab sib tshooj stainless hlau braided graphite nplhaib los ntawm US GARLOCK Company.Qhov ceev ntawm pre-formed graphite nplhaib yog 1120kg / m3.Thiab tag nrho cov packing muaj corrosion inhibitor.Cov ntsiab lus ntawm lim muaj peev xwm chloride yog <100ppm nyob rau hauv uas muaj cov nplaum, lubricants thiab lwm yam additives, nyob rau hauv thiaj li yuav tiv thaiv corrosion ntawm qia los ntawm CI thiab fugitive emissions ntawm nruab nrab.

4.Cov txheej txheem casting ntawm qhov chaw siab yog nyob rau hauv lub hauv paus ntawm cov txheej txheem casting ntawm kev soj ntsuam kev ua raws, uas muaj 100% kev kuaj tsis muaj kev puas tsuaj.Cov khoom semi-tiav ntawm cov castings yog raws li cov kev cai ntawm high-temperature thiab high-pressure hydrogenation li qub;Machining thiab sib dhos yog nruj me ntsis tswj kev ua thiab kev sib dhos.

| Technical specification | |

| Loj | 2 "~ 24" |

| Kev ntsuas | Chav Kawm 600 ~ Chav Kawm 2500 |

| Tus qauv tsim | API 600, API 6D, BS 1873, ASME B16.34 |

| Kev kuaj & tshuaj xyuas | API 598, API 6D, ISO 5208, ISO 14313, BS 5146 |

| Khoom siv lub cev | Carbon Steel, Stainless Hlau, Alloy Steel, Duplex Steel |

Lus Cim: Qhov ntau thiab tsawg ntawm serial valve txuas flange tuaj yeem tsim raws li cov neeg siv khoom xav tau.

Post lub sij hawm: May-19-2022