1. Scope

Cov DN ntau yam suav nrog DN15mm ~ 600mm (1/2 "~ 24") thiab PN ranges ntawm PN1.6MPa ~ 20MPa (ANSI CLASS150 ~ 1500) threaded, flanged, BW thiab SW viav vias thiab nqa daim tshev valve.

2. Kev siv:

2.1 Lub valve no yog los tiv thaiv qhov nruab nrab ntws rov qab hauv cov yeeb nkab.

2.2 Valve khoom raug xaiv raws li qhov nruab nrab.

2.2.1WCB valve yog tsim rau dej, chav thiab roj nruab nrab thiab lwm yam.

2.2.2SS valve yog tsim rau nruab nrab corrosion.

2.3 Kub:

2.3.1Common WCB yog haum rau kub -29 ℃ ~ + 425 ℃

2.3.2Alloy valve yog haum rau kub≤550 ℃

2.3.3SS valve yog tsim rau kub-196 ℃ ~ + 200 ℃

3. Cov qauv thiab kev ua haujlwm zoo

3.1 Cov qauv hauv paus yog raws li hauv qab no:

3.2 PTFE thiab saj zawg zog graphite yog saws rau kev puas tsuaj gasket los xyuas kom meej sealing kev ua tau zoo.

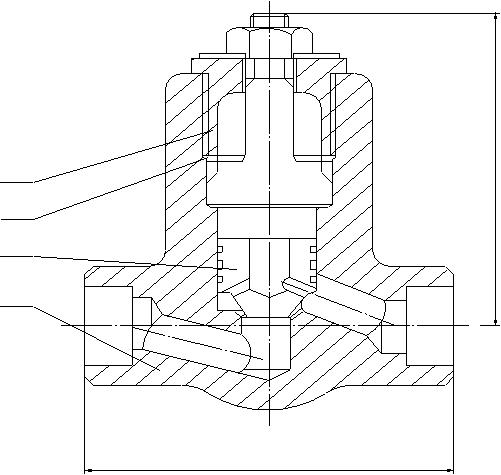

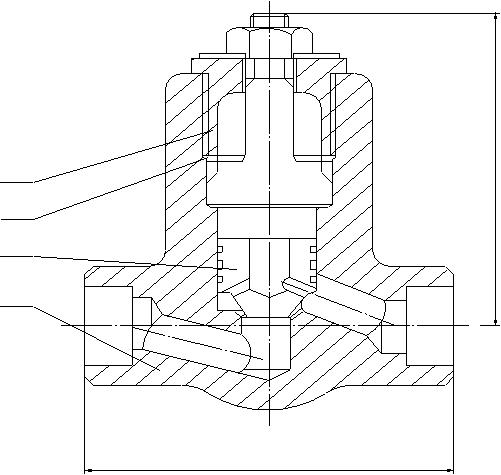

(A) Vuam forged siab siab self-sealing lifting kos valve

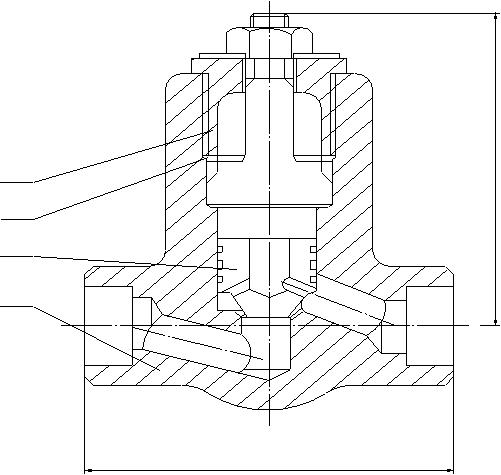

(B) Welding forged lifting check valve

1. lub cev 2. disc 3. gasket 4. lub kaus mom

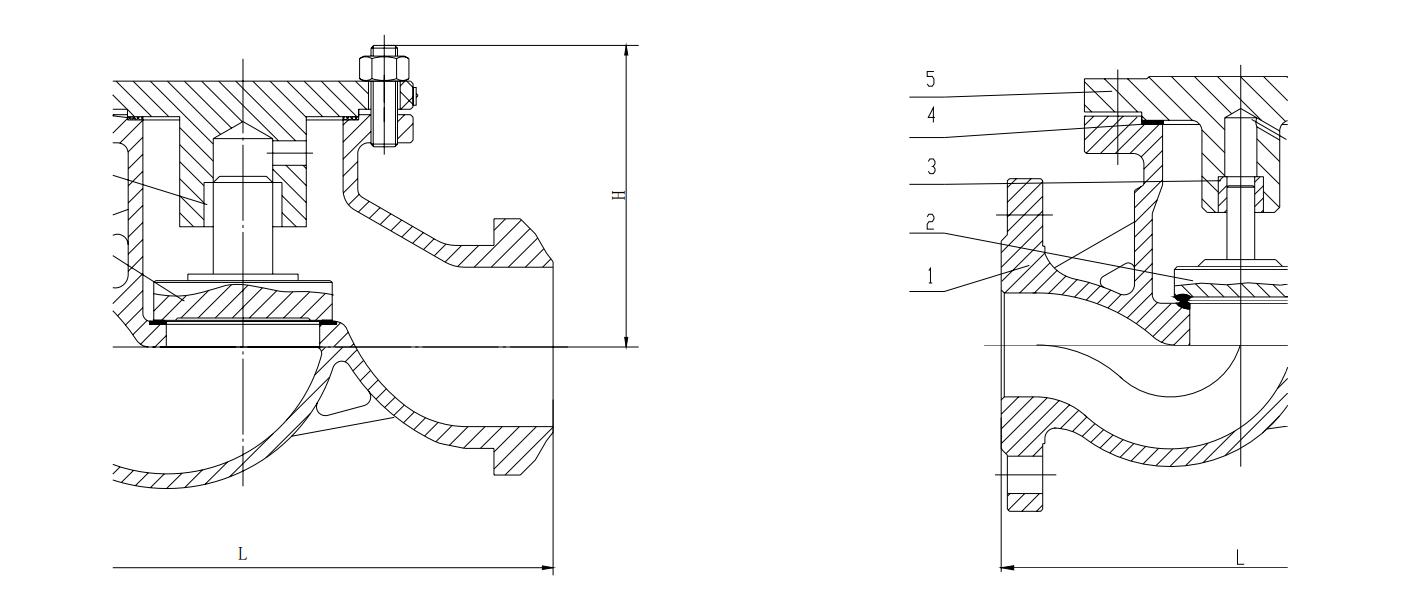

(C) BW Lifting Check Valve

(D) Flanged Check Valve

1. Lub cev 2. Disc 3. Ncej 4. Gasket 5. Bonnet

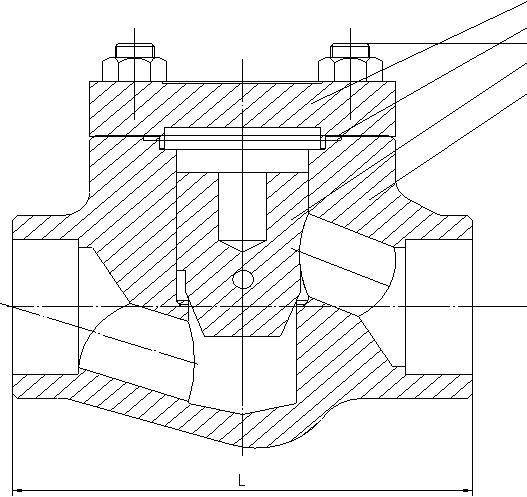

(E) BW Swing Check Valve

(F) Flanged Swing Check

1. Lub Cev 2. Rooj 3. Disc 4. Rocker Arm 5. Pin Shaft 6. Yoke 7. Gasket 8. Bonnet

3.3 Cov khoom siv tseem ceeb

| Lub npe | Khoom siv | Lub npe | Khoom siv |

| Lub cev | Carbon Steel, SS, Alloy hlau | Pin Shaft | SWB, Cr13 |

| Rooj Seal | Surfacing13Cr, STL, Roj Hmab | Yawg | Carbon Steel, SS, Alloy hlau |

| Disc | Carbon Steel, SS, Alloy hlau | Gasket | PTFE, Flexible Graphite |

| Rocker caj npab | Carbon Steel, SS, Alloy hlau | Bonnet | Carbon Steel, SS, Alloy hlau |

3.4 Daim Ntawv Qhia Ua Haujlwm

| Kev ntsuas | Kev ntsuas lub zog (MPa) | Kev ntsuas foob (MPa) | Huab cua foob (MPa) |

| Chav Kawm 150 | 3.0 | 2.2 | 0.4 ~ 0.7 hli |

| Chav Kawm 300 | 7.7 | 5.7 | 0.4 ~ 0.7 hli |

| Chav Kawm 600 | 15.3 | 11.3 | 0.4 ~ 0.7 hli |

| Chav Kawm 900 | 23.0 Nws | 17.0 Nws | 0.4 ~ 0.7 hli |

| Chav Kawm 1500 | 38.4 ib | 28.2 ib | 0.4 ~ 0.7 hli |

| Kev ntsuas | Kev ntsuas lub zog (MPa) | Kev ntsuas foob (MPa) | Huab cua foob (MPa) |

| 16 | 2.4 | 1.76 ib | 0.4 ~ 0.7 hli |

| 25 | 3.75 ib | 2.75 ib | 0.4 ~ 0.7 hli |

| 40 | 6.0 | 4.4 | 0.4 ~ 0.7 hli |

| 64 | 9.6 ib | 7.04 ib | 0.4 ~ 0.7 hli |

| 100 | 15.0 Nws | 11.0 Nws | 0.4 ~ 0.7 hli |

| 160 | 24.0 Nws | 17.6 ib | 0.4 ~ 0.7 hli |

| 200 | 30.0 Nws | 22.0 Nws | 0.4 ~ 0.7 hli |

4. Kev xav ua haujlwm

Kos valve cia li qhib thiab kaw lub disc kom tsis txhob nruab nrab ntws rov qab los ntawm qhov nruab nrab ntws.

5. Siv tau cov qauv valve tab sis tsis txwv rau:

(1) API 6D-2002 (2) ASME B16.5-2003

(3) ASME B16.10-2000 (4) API 598-2004

(5) GB/T 12235-1989 (6) GB/T 12236-1989

(7) GB/T 9113.1-2000 (8) GB/T 12221-2005 (9) GB/T 13927-1992

6. Cia & Kho & Txhim Kho & Ua Haujlwm

6.1 Lub valve yuav tsum tau muab cia rau hauv qhov chaw qhuav thiab qhov cua zoo.

6.2 li qub nyob rau hauv lub sij hawm ntev cia yuav tsum tau soj ntsuam thiab ntxuav tsis tu ncua, tshwj xeeb tshaj yog lub rooj zaum lub ntsej muag kom tsis txhob muaj kev puas tsuaj ntawm nws, thiab lub rooj zaum lub ntsej muag yuav tsum tau coated nrog xeb inhibiting roj.

6.3 Valve marking yuav tsum tau kuaj xyuas kom ua raws li kev siv.

6.4 Valve kab noj hniav thiab sealing nto yuav tsum tau xyuas ua ntej installation thiab tshem tawm cov av yog tias muaj.

6.5 Xub kev taw qhia yuav tsum zoo ib yam li cov dej ntws.

6.6 Lifting ntsug disc kos valve yuav tsum tau ntsia vertically rau cov kav dej.Lifting kab rov tav disc kos valve yuav tsum tau ntsia horizontally rau lub raj xa dej.

6.7 Cov kev vibration yuav tsum tau kuaj xyuas thiab cov kav dej nruab nrab ntawm lub siab hloov yuav tsum raug sau tseg kom tsis txhob muaj kev cuam tshuam dej.

7.Qhov teeb meem tshwm sim, ua rau thiab kev ntsuas kho

| Teeb meem tshwm sim | Ua rau | Kev ntsuas ntsuas |

| Disc tsis tuaj yeem qhib lossis kaw |

| |

| Cov dej ntws tawm |

| |

| Suab nrov thiab kev vibration |

|

8. Warranty

Tom qab lub valve tau muab tso rau hauv kev siv, lub sijhawm lav ntawm lub valve yog 12 lub hlis, tab sis tsis pub tshaj 18 lub hlis tom qab hnub xa khoom.Thaum lub sijhawm lav, cov chaw tsim khoom yuav muab kev pabcuam kho lossis cov khoom seem dawb rau kev puas tsuaj vim cov khoom siv, kev ua haujlwm lossis kev puas tsuaj yog tias kev ua haujlwm raug raug.

Post lub sij hawm: May-19-2022